Does your treadmill turn on and turn the belt but it stops as soon as you step on it? Or maybe the belt stops spinning under higher loads? There are 6 possible reasons for this which we’ll go through in this article. We’ll also explain how to diagnose and fix these problems.

If your treadmill belt doesn’t move when you stand on it, it could be because you’ve exceeded the recommended weight limit. Other potential causes include a damaged deck, a worn walking belt, improper lubrication, poorly tensioned roller bars, a malfunctioning drive belt, or a defective motor.

Let’s dive into what causes these problems, how they make the belt stop spinning, how to diagnose them and how to fix them.

Reasons Your Treadmill Belt Stops When Stepping On

1. You Exceed the Weight Limit

The most straightforward reason why a treadmill stops moving when you stand on it is that you exceed the weight limit. Before checking the treadmill for any mechanical issues, check the owner’s manual for the recommended weight capacity.

Exceeding the load limit of a treadmill can cause the belt to stop when you step on it. The belt can stick to the deck, preventing movement.

Budget treadmills usually have a weight limit from 200 to 300 pounds (91 kg to 136 kg). More expensive treadmills offer more lenient weight capacities, from 300 pounds up to 500 pounds (136 kg to 227 kg) for higher-end models.

When you exceed a treadmill’s weight limit, the belt will stick to the deck, preventing movement. However, if you’re within the manufacturer’s weight limit and the belt still won’t move, try some other tips in this article.

Suggested: Can you lose belly fat by just using a treadmill?

2. The Deck or Walking Belt Is Damaged

The deck is the surface on which the belt rotates. It should be smooth and sturdy. There should be no cracks, pits, or grooves. Most treadmill decks are made of wood or medium to high-density fiberboard, so make sure no wood is exposed.

A worn or damaged deck can create extra friction when the belt spins. At some point, the motor won’t be able to overcome the added friction and the belt stops spinning.

Once you’ve ensured that the deck is in good condition, move on to the walking belt. The walking belt rotates over the deck, creating friction. Over time, the friction wears down the belt—and a worn belt will stop moving under load. If the belt is worn, you’ll need to replace it. Find the 4 key signs you should replace your treadmill belt here.

Examine the belt for any visible signs of damage. Check it from end to end and then rotate the belt to examine the opposite side. After you’ve checked the belt, take a look at the seam.

The seam is thicker than the rest of the belt and easy to locate. Look for a diagonal pattern where the belt joins together. It should be securely stitched together with no signs of fraying or pulling apart. The underside of the seam should feel ridged with no large lumps or splits. If there are signs that the seam is separating, you’ll need to purchase and install a new belt.

If the belt seems to be in good condition, test it further with a coast or incline test.

Suggested: How much does a treadmill belt replacement cost?

Coast Test

A coast test determines how much friction is created by the belt on the deck. To complete this test, follow these instructions:

- Set the treadmill to the lowest incline setting.

- Stand on the treadmill and power it on.

- Turn the speed to 3 mph (4.83 kph) and walk.

- Pull the safety lock out of the treadmill and count how many steps it takes for you to come to a complete stop.

On most treadmills, it takes between two and three steps to stop completely. Therefore, it could indicate high friction if it takes less than two steps to come to a complete stop. If that’s the case, you may need to adjust the tension of your walking belt or check that the motor is in good working order. We’ll discuss how to adjust the tension and check the motor later in this article.

Note: Some higher-end treadmill models may stop immediately even with a belt in good condition, so this is not a 100% foolproof test.

Incline Test

If your treadmill has an incline option, you can test the belt’s condition using an incline test. An incline test uses gravity to determine whether the belt is working correctly. Complete an incline test using the following instructions:

- Get on the treadmill.

- Adjust the settings so that the treadmill is on the maximum incline.

- Power on the treadmill.

- Turn the speed up to 3 mph (4.83 kph).

If the treadmill belt moves at the maximum incline level but stops or slows down at low or no incline, the walking belt is the likely culprit. When you’re walking on a maximum incline, gravity works in your favor, reducing friction.

Note: Severely damaged belts may not work on minimum or maximum incline. In that case, you cannot eliminate the problem using this test. However, if the belt is heavily damaged, there should be some observable signs.

Suggested: 12 Tips for buying a second hand treadmill

3. The Belt Needs Lubrication

If the treadmill continues to stop under load, but the walking belt and deck are in good condition, and you aren’t exceeding the weight limit, the belt might need lubrication. This is likely the case if you’ve stored the treadmill away for a while. Dirt, dust, and other debris get caught under the belt, causing it to stick.

A treadmill belt that’s not properly lubricated can cause the treadmill to stop when stepping on. The belt creates too much friction to move as needed. Simply lubricating the belt and deck is enough to fix this problem provided both are still in good condition.

Most standard treadmills require manual lubrication to keep them in good working order. Lubricant reduces friction, allowing the belt to move freely, and extends the life of the machine. Without proper lubrication, the treadmill belt will become brittle and more prone to damage. A dry, damaged belt causes the motor to have to work harder, which pulls more amps. Not only can inadequate lubrication ruin the belt, but it can destroy the treadmill’s motor as well.

To determine whether your treadmill walking belt needs lubrication, touch the surface of the walking deck under the belt. It should feel slightly waxy or oily. If it feels dry, you’ll need to lubricate the belt.

Most treadmill lubricants are silicone or silicone-based. Check the owner’s manual to see what type of lubricant the manufacturer recommends for your machine.

Note: Some high-end treadmills offer self-lubrication systems. Check your owner’s manual to determine whether your treadmill has a self-lubrication system. If it does, do not add lubrication manually. Improper lubrication can damage a walking belt.

Suggested: Is 30 minutes on a treadmill to see results?

How To Lubricate Your Treadmill’s Walking Belt

Most manufacturers will provide instructions on how to apply lubrication to the walking belt. We will provide general instructions below.

- Unplug the treadmill.

- Turn the walking belt manually until the seam meets the roller at the front of the machine.

- Lift the belt in the center on one end of the treadmill.

- Apply ½ of the lubricant in a zig-zag pattern under the belt while holding it up.

- Slide your hand along the belt and continue adding lubricant until you’ve applied it from one end to another.

- Turn the belt manually again until the seam meets the roller at the back of the machine.

- Lift the belt again and apply the rest of the lubricant as before.

- Power on the treadmill. Walk for ten minutes at 2 mph (3.2 km/h).

Walking on the belt once you’ve applied lubricant evenly distributes the oils across the walking belt and deck.

4. The Roller Bars Need Readjusting

Poor roller bar adjustment can stop a treadmill walking belt in its tracks when weight is applied. This is typically caused by shifted rollers, the distance between rollers, or a stretched belt.

How To Adjust a Treadmill’s Roller Bars

For this fix, you will only be working with the rear roller. The front roller connects to the motor, so to adjust the tension of that roller, you will have to access the motor’s drive belt. We discuss that more in-depth in the section titled “The Drive Belt Needs an Adjustment or Replacement.”

To adjust the rear roller bolts, use a hex spanner. This tool typically comes with treadmills—if you have a second-hand treadmill, you may need to purchase this tool.

- Turn off and unplug the treadmill.

- Locate the bolts on the back roller bar. There will be bolts on both the left and right sides—sometimes they’re hidden under plastic caps.

- Twist the bolts a ¼ turn clockwise to tighten them. Adjust both sides equally to prevent the roller bar from sliding off-center.

- Plug the treadmill in and power it on. Stand on the treadmill to see if this resolved the problem.

- If not, adjust the screws again. Complete another ¼ clockwise turn on both sides. Repeat steps 1 to 3 for a third time.

Do not tighten the bolts more than three times. Over-tightening will prematurely stretch the walking belt and cause the motor to work harder.

If the belt continues to stop under load after tightening the roller bar, the culprit may be the drive belt or motor, which we’ll discuss later in this post.

Suggested: Are treadmill belts universal?

Centering a Treadmill Walking Belt

After you’ve adjusted the roller bars, the belt might be slightly off-center. To recenter the belt, use the following instructions:

- Turn off and unplug the treadmill.

- Place one foot on the walking belt, keeping the other foot planted firmly on the floor.

- Slide the belt backward using your foot until the belt is centered.

- Remove your foot from the belt.

- Plug the machine in and run it at low speed to check that the belt is centered and moving correctly.

If the belt is still off-center, you’ll need to adjust the bolts on the roller bars again. Pay attention to the side that the belt is slipping toward. Tighten the roller bolt on the side it’s shifting towards, or loosen the bolt on the opposite side.

After you’ve centered the belt, check the tension. If you can lift the belt 2 to 3 inches (5 – 7 cm) off the walking deck, the tension is correct, and the belt is positioned correctly. Sometimes a walking belt needs lubrication after an adjustment. See the section titled “The Belt Needs Lubrication” for more information on lubricating the walking belt.

5. The Drive Belt Needs an Adjustment or Replacement

So, you’ve ensured that you don’t exceed the treadmill’s weight limit, checked the walking belt and deck for damage, lubricated the belt, and checked the rollers—but the machine still stops moving under weight. What now?

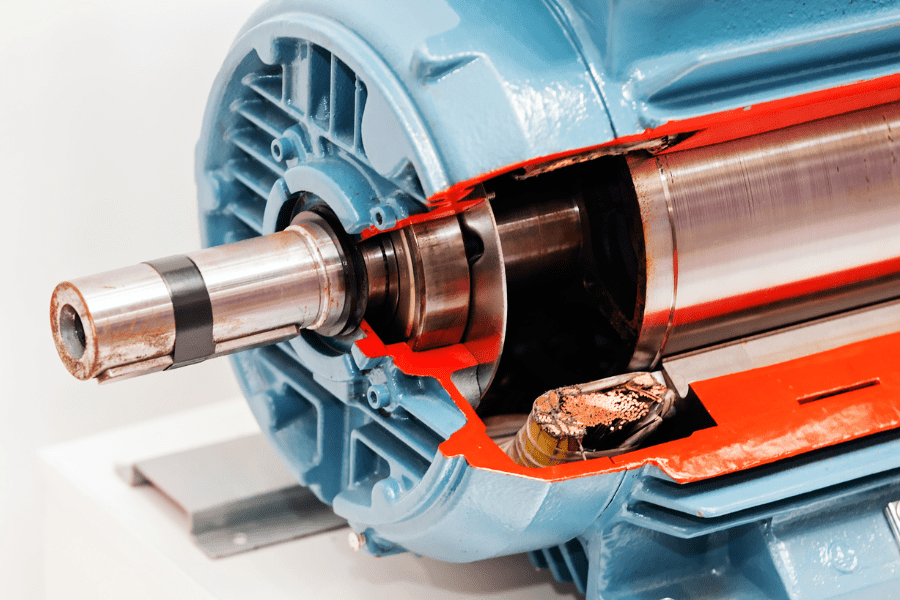

The drive belt connects the treadmill’s motor to the walking belt. If it’s worn or too loose, it can cause the walking belt to stop while the motor keeps spinning.

If the belt moves properly when nobody is on the treadmill and stops only when weight is applied, the problem could be the drive belt. This isn’t the same belt as the one you walk on, it’s the one between the motor and front roller. It connects the walking belt to the motor.

If a treadmill’s drive belt is worn out or loose, it can cause the walking belt to stop even though the motor keeps running.

Troubleshooting a Treadmill Drive Belt

Before disassembling anything, troubleshoot the drive belt to be certain it needs repair:

- Turn the treadmill off, unplug it, and remove the motor hood.

- Wiggle the drive belt gently. There should be about ½ inch of movement. If there’s more play, it’s too loose. If there’s less, it’s too tight.

- Plug the machine back in (while the hood is off) and turn it on at low speed (be extremely careful during this step—keep hands and fingers away from the motor to avoid serious injury).

- Examine the front roller. If the front roller stops turning, but the drive belt continues to spin, the roller is the likely culprit. If the roller and the drive belt stop turning, the drive belt needs to be readjusted or replaced.

How To Adjust a Treadmill Drive Belt

Once you’ve determined that the issue is with the drive belt, you’ll need to readjust the tension. You may need a friend to help you with this fix.

Follow all instructions in your owner’s manual—do not attempt this fix if you’re unsure of what you’re doing. Over-tightening a drive belt is easy to do and can damage the treadmill and void the warranty.

- Unplug the treadmill. The hood should still be off after troubleshooting—if not, remove the motor hood again.

- Locate and loosen the motor’s mounting bolts.

- Adjust the motor so that the drive belt feels nice and tight (this step will require some force).

- Have a friend retighten the mounting bolts as you hold the motor in place, keeping the drive belt tight.

- Plug the treadmill in and do a test run. If the drive belt pulley and the roller bar continue to stop, replace the drive belt.

Sometimes drive belts get stretched and no longer provides the “grip” needed to turn the roller bar. Drive belts typically have part numbers printed on them. Use this number to determine what style you need when replacing the belt.

6. The Motor Is Defective

If all other fixes fail and your treadmill continues to stop or slow down when you step on it, it could be a problem with the motor.

Suggested: How much does a treadmill motor replacement cost?

How To Check for a Burnt Control Board

Sometimes the motor becomes weak and no longer has the power to spin the roller to drive the belt. To check the motor, use the following instructions:

- Turn off and unplug the treadmill.

- Remove the motor hood.

- Examine the motor control board. Look for burns.

Burn marks on the control board indicate burnt resistors. In that case, the motor control board needs replacing. Check the owner’s manual or reach out to the manufacturer to order a replacement motor control board for your treadmill.

How To Check for Damaged Motor Brushes

If there are no burn marks or other visible signs of damage to the motor, you can check the motor brushes. However, this test is potentially dangerous, and a professional or experienced treadmill repair person should perform the repair.

- Turn off and unplug the treadmill.

- Remove the motor hood.

- Plug in and turn on the treadmill. Set it to a low-speed setting.

- Determine which way the motor spins.

- Use a long object (NEVER use your hands or fingers) to apply gentle, downward pressure on the flywheel in the direction it turns.

If you can slow the motor by applying pressure with a shaft or other object, you may need a motor brush replacement.

Finally, if the motor seems to be in good shape, it could be that the motor is demagnetized. Testing for demagnetization requires disassembly of the motor and should be performed by a qualified professional.

Conclusion

Treadmills—both low and high-end—require regular maintenance to ensure they work properly and last for years to come. Sometimes we forget about our treadmills, storing them away and inadvertently causing issues with the machine. When we pull them back out, the problems are apparent. One common problem is that the treadmill stops moving when you step on it.

When a treadmill stops under human weight, there are several potential causes, from exceeding the weight limit to a defective motor. Fortunately, most of the problems that cause a belt to stop moving have easy fixes that you can do at home.

Sources

- Work While Walking: Do Treadmill Desk Weight Ratings Really Matter?

- Sports Rec: How Do Treadmills Work?

- Treadmill Running Belts: FAQs

- Cash for Treadmills: Tips To Save Your Treadmill from the Fitness Graveyard

- Sports Rec: Is My Treadmill Roller Bad?

- Pro Form Fitness: Tightening Your Drive Belt

- Treadmill Engineer: Treadmill Motors – How Do They Work?